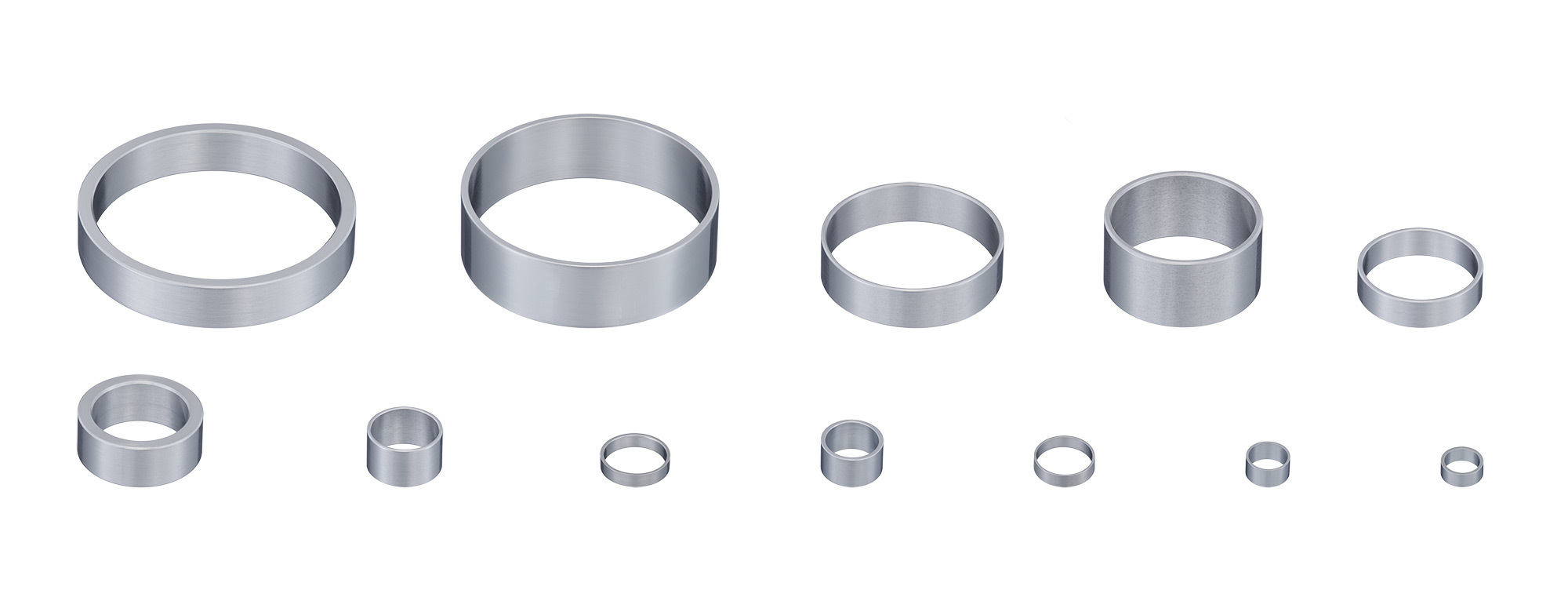

SMA Tubular Memory Lock Ring

SMA is very simple, and uses the one-way shape memory effect in constrained recovery for the most popular application that is the weld less tubes joining。One coupling component is machined, in the high temperature phase, with an inside diameter slightly smaller than the outside diameter of tubes to join. Then the coupling is cooled to the martensitic phase (usually at liquid nitrogen), and mechanically expanded to have an inside diameter larger than the tubes to join. Both tubes are inserted into the cooled coupling. Then, when the coupling is warm up to the service temperature, it transform to the beta phase and shrink back to a diameter smaller than the tubes, doing a strong joining force and generating a highly reliable metal-to-metal seal, even in high vibration conditions.

Technical Parameters

-

Unloaded heating shrinkage initiation temperature: As ≥ 45℃

-

Unloaded heating shrinkage completion temperature: Af ≤ 100℃

-

Assembly heating temperature: 165℃ ~ 200℃

-

Operating temperature range: -55℃ ~ 200℃

-

Shape memory recovery rate: ε0 ≥ 5%

-

Shape memory recovery stress: σR ≥ 300 MPa

-

Customization available upon customer request.

Size

-

ID: from 2.40mm to the above

-

Wall thickness: from 0.16mm to the above

-

Length: from 1.00mm to the above

-

For more information, Contact us